+852 2363 2511

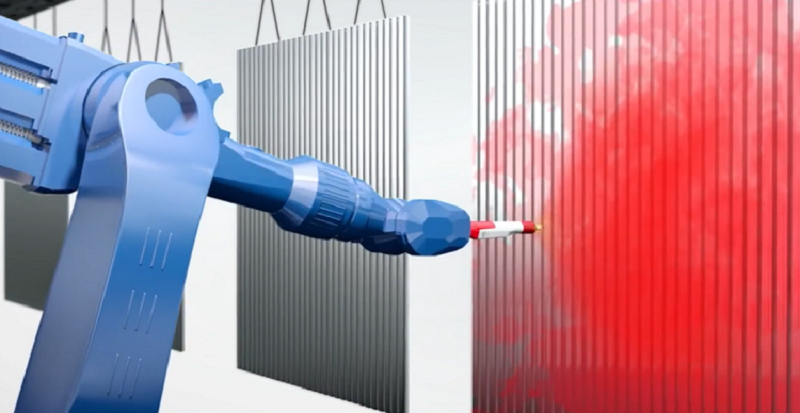

When it comes to achieving a top-notch paint job, surface preparation is the name of the game. One such method that goes a long way in accomplishing this goal is sandblasting. It's the professional's secret weapon to make sure their working surface is flawless and perfect for an excellent finish. Sandblasting removes even the stubborn rust, dust, dirt or old paint more completely than any other procedure and provides for a perfect finish. It plays an important part in making sure that there will be no particles present to hinder good adhesion or spoil otherwise fantastic painting.

Skipping this step is like skipping the foundation when building a house—you're just asking for trouble. The process entails abrasive materials such as sand, glass beads, steel grits, and acrylic to get what it's made for. These abrasives are propelled onto the surface of your object with accuracy and force. And voila. You have yourself a perfectly enhanced surface free from peeling paint imperfections, oil residue, rust marks or dust particles. But that isn't where the story ends on sandblasting; there's always more than what meets the eye.

Sandblasting, also known as abrasive blasting, entails air pressure directed abrasives at high speed towards a surface. This technique comes in two forms: water-driven and air-driven blasting. The former is used for prepping concrete or brick surfaces as it creates little damage on the surface. When trying to prepare metal surfaces, the air-driven type of sandblasting has been found effective in these fronts. It ensures that there's no moisture buildup nor any water because metals need to be dry during surface preparation.

Now, let's dive into the machinery that makes sandblasting possible—the sandblaster, or sandblasting machine. This versatile tool finds its place in various industries, including construction, automotive, and marine applications. There are different types of sandblasting machines at your disposal, each with its own unique features. These include the suction blasting machine, the wet sandblasting machine, and the pressure sandblasting machine.

Wondering how the magic happens? It all starts with the sand, which is loaded into the sandblaster's chamber at the top of the machine. Then, a regular air compressor comes into play, forcefully propelling the sand through a user-friendly handheld nozzle. You have the freedom to adjust the pressure, typically ranging from 50 to 130 PSI, depending on your specific application.

Whenever you are blasting that abrasive sand over the surface, the grit and power does your heavy lifting. But sandblasting is somewhat more effective when prepping concrete surfaces. It smoothens the surface, removes excess material, and makes it pristine.

Here are the reasons for you to adopt sandblasting.

Versatility: You may be in need of getting rid of that old paint or rejuvenating pavement. sandblasting will do the cleaning and restore the surfaces. Its flexibility that embodies high-quality finishes, and breeze painting. It doesn’t matter if you are dealing with rugged pavement or delicate wooden tables. It doesn't matter if they are precision components like small gears. Sandblasting covers it all.

Speed and Efficiency: Do you need that smooth surface in a timely manner? Sandblasting makes the whole process easy. Don't worry about complex preparations. No more strong chemicals and laborious scrubbing. It's time to save time and cut down on costs. Alsi cleaning is going to be easy since you only have to collect the trash from the booth. If you're using glass beads, you can even recycle them. Compare this to the time-consuming process of hand-sanding metal with sandpaper, and you'll quickly see the appeal of sandblasting.

Cost Effectiveness; Manufacturers are constantly searching for affordable solutions, for surface preparation. Many other methods available in the market can be excessively costly or overly complicated for businesses. However sandblasting stands out as a cost time efficient option when it comes to preparing surfaces for painting or finishing. Unlike surface treatments like stripping and degreasing which can be labor intensive and inconvenient due to their reliance on harmful chemicals, sandblasting ensures that production lines and projects stay on track while remaining affordable.

Safety First; Sandblasting is a technique that prioritizes safety by eliminating any risk of releasing toxic substances into the atmosphere. The abrasive materials used in sandblasting are non toxic eliminating concerns about inhaling particles. Moreover there is no need to handle materials reducing the risk of exposure related health issues. When it comes to disposing of the materials after sandblasting you can rest assured knowing that it is a straightforward process.

It is undeniable that sandblasting offers versatility, efficiency and environmental friendliness when it comes to preparing a range of surfaces. Its numerous benefits make it an excellent choice, for anyone involved in the surface preparation industry.

If you're thinking about starting a project or require equipment and support, for your sandblasting requirements you can rely on Ramseier Koatings. We are a partner who can help you purchase the equipment and offer expert guidance in setting up sandblasting systems. By incorporating the effectiveness of sandblasting you can enhance your surface preparation techniques. Discover a multitude of opportunities.